Printing Design Images: A Complete Guide for Professional Results

Printing design images plays a crucial role in modern branding, marketing, and packaging. From product labels to promotional materials, the quality of printed visuals directly affects how a brand is perceived. Businesses that understand printing design images gain better control over colour accuracy, sharpness, and consistency, which ultimately builds trust with customers. In today’s competitive UK market, printing is no longer just about transferring an image onto paper. It is about precision, planning, and professional execution.

Understanding Printing Design Images

Printing design images refers to the process of preparing and reproducing digital artwork onto physical materials. These materials may include paper, cardboard, vinyl, fabric, or packaging substrates. The goal is to maintain visual accuracy while ensuring durability and consistency across print runs.

Unlike digital images viewed on screens, printed images rely on inks, resolution, and surface texture. This means designs that look perfect on a monitor may appear dull or blurred when printed if not prepared correctly. Understanding this difference is the foundation of successful printing design images.

Why Printing Design Images Matters for Branding

High-quality printing design images create a strong first impression. Customers often judge a brand by its printed materials, including packaging, brochures, and labels. A poorly printed image can make a premium product look cheap, even if the design itself is strong.

In contrast, well-executed printing design images communicate professionalism and reliability. Colours appear vibrant, text remains sharp, and imagery reflects the intended mood. This consistency strengthens brand recognition and improves customer trust, especially in retail environments.

Preparing Images for Print

Resolution and Image Quality

Resolution is one of the most important factors in printing design images. For professional printing, images should be prepared at 300 DPI. Lower resolutions often result in pixelation and blurred edges, which reduce print quality.

High-resolution images also allow printers to reproduce fine details accurately. This is especially important for packaging designs, where small text and intricate graphics are common.

Colour Modes for Accurate Printing

Digital screens use RGB colour mode, while printing relies on CMYK. Converting images to CMYK before printing ensures colour accuracy. Without conversion, colours may shift unexpectedly during printing.

Professional designers often adjust colours manually after conversion. This step helps maintain vibrancy and avoids dull or muddy tones in the final print.

File Formats That Printers Prefer

Printers usually prefer formats such as PDF, TIFF, or EPS. These formats preserve image quality and layout integrity. JPEG files can be used, but only at the highest quality settings.

Using the correct file format ensures smoother production and fewer errors during printing design images.

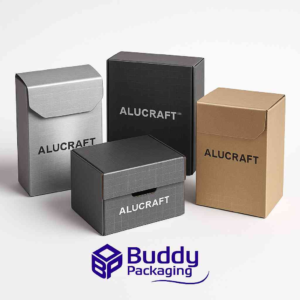

Printing Design Images for Packaging

Packaging is one of the most demanding applications for printing design images. It requires precision, durability, and consistent branding. High-quality printing enhances shelf appeal and helps products stand out in crowded markets.

Businesses investing in Custom Packaging often rely heavily on professional image printing to reflect their brand values. Clear visuals and accurate colours create a premium feel that customers notice immediately.

Printing on packaging also involves material considerations. Cardboard, kraft paper, and coated surfaces absorb ink differently. Designers must adjust image contrast and saturation based on the chosen material to achieve the desired result.

Common Printing Techniques and Their Impact

Digital Printing

Digital printing is ideal for short runs and fast turnaround times. It delivers consistent quality and allows easy customisation. Printing design images digitally works well for promotional materials and limited-edition packaging.

Offset Printing

Offset printing is preferred for large volumes. It offers superior colour accuracy and cost efficiency at scale. Brands that require consistent printing design images across thousands of units often choose offset printing.

Flexographic Printing

Flexographic printing is commonly used for packaging and labels. It handles various materials and provides durable results. Proper image preparation is essential to avoid distortion during printing.

The Role of Image Design in Marketing Materials

Marketing materials rely heavily on printing design images to communicate messages quickly. Brochures, flyers, and posters must capture attention within seconds. High-quality imagery ensures that messages are clear and engaging.

Consistent image printing across marketing channels strengthens brand identity. Customers recognise familiar colours and visuals, which increases recall and trust. Designers often seek packaging design inspiration to align marketing visuals with product packaging. This approach creates a unified brand experience across physical and digital touchpoints.

Avoiding Common Mistakes in Printing Design Images

Many printing issues arise from simple oversights. One common mistake is using low-resolution images sourced from the web. These images are unsuitable for print and often result in poor quality.

Another issue is ignoring bleed and trim areas. Designs without proper bleed may lose important elements during cutting. Including bleed ensures that printing design images extend fully to the edges. Incorrect colour profiles also cause problems. Always confirm printer specifications before finalising artwork. This step prevents unexpected results and costly reprints.

Working with Professional Printers

Choosing the right printer is essential for successful printing design images. Professional printers offer guidance on file preparation, materials, and finishes. Their experience helps avoid errors and ensures consistent quality.

Clear communication with printers is key. Sharing expectations, samples, and brand guidelines helps align results with your vision. Visiting a local printer can also be beneficial. Many businesses prefer working with providers near the Buddy Packaging Location for easier collaboration and faster turnaround times.

Sustainability in Printing Design Images

Sustainability is becoming increasingly important in the UK printing industry. Eco-friendly inks, recycled materials, and efficient processes reduce environmental impact.

Designers can support sustainability by optimising images to use less ink without compromising quality. Choosing lighter colour palettes and avoiding excessive coverage contributes to greener printing practices.

Sustainable printing design images appeal to environmentally conscious consumers. This approach enhances brand reputation while supporting responsible business practices.

Quality Control and Proofing

Proofing is a critical step in printing design images. Digital proofs provide an initial preview, but physical proofs offer a more accurate representation. Colours, textures, and finishes are easier to assess in print.

Reviewing proofs carefully prevents costly mistakes. Check text clarity, colour accuracy, and alignment before approving full production. Quality control ensures that the final product meets professional standards.

The Future of Printing Design Images

Technology continues to shape the future of printing. Advances in colour management, automation, and sustainable materials are improving efficiency and quality.

Personalisation is also growing. Variable data printing allows brands to customise images for different audiences. This trend makes printing design images more dynamic and engaging.

As digital and physical branding merge, the demand for high-quality printed visuals will remain strong. Businesses that invest in professional printing practices will stay competitive.

Achieving Excellence in Printing Design Images

Printing design images is both an art and a technical process. It requires careful preparation, professional knowledge, and attention to detail. From resolution and colour management to printing methods and sustainability, every step influences the final result.

Businesses that prioritise quality in printing design images gain a competitive advantage. Their materials look professional, consistent, and trustworthy. Whether you are producing packaging, marketing materials, or promotional items, investing in proper printing practices pays off.

Frequently Asked Questions About

What resolution is best for printing design images?

The ideal resolution for printing design images is 300 DPI. This ensures sharp and clear results without pixelation.

Why do colours look different when printed?

Colours appear different because screens use RGB, while printing uses CMYK. Converting and adjusting colours before printing improves accuracy.

Can I use online images for printing?

Most online images are low resolution and unsuitable for printing. Always use high-quality, licensed images designed for print use.

How do I choose the right printing method?

The choice depends on volume, material, and budget. Digital printing suits short runs, while offset printing works best for large quantities.

Is proofing necessary before printing?

Proofing is essential. It helps identify errors and ensures that printing design images match expectations before full production.