Packaging Design Nets: The Complete Guide to Mesh & Net-Based Packaging

When a customer holds a product, the first impression counts. Packaging isn’t just protection — it’s messaging, experience, and branding. Among the many packaging methods, packaging design nets stand out as an elegant hybrid between structure and openness. They let your product breathe, be partly visible, and still present a polished, branded appearance. You’ll see them in fruit net bags, mesh pouches for cosmetics, or wireframe-style sleeves around boxes. For brands aiming for sustainability and engagement, nets can be a smart choice. But executing them properly requires design precision, material knowledge, and brand alignment. This guide will walk you through everything from structural basics to advanced tips, so your packaging design nets will not just look good — they’ll perform beautifully.

What Are Packaging Design Nets

A “net” in structural design is a 2D layout (an unfolded shape) that folds into a three-dimensional form. In packaging, that net becomes the shell or structure you wrap, fold, or tension into a final container. Thus, packaging design nets blend this structural idea with net or mesh materials, or use cut-outs and perforations in solid material to achieve a netted appearance. The aim is to allow visual connectivity between inside and outside, or to incorporate airflow, while still retaining the strength and branding of conventional packaging.

Why Use Nets in Packaging

Transparency and trust play a major role in modern consumer behaviour. Customers like to see what’s inside — especially in food, cosmetics, and handmade goods. Nets provide that partial reveal while preserving protection. They also promote ventilation and freshness, making them ideal for products like fruits, vegetables, and baked goods. A key benefit is their lightweight and material-efficient nature; by using net structures or perforations, manufacturers can cut down on unnecessary solid material, reducing costs and environmental impact. Aesthetic distinctiveness also sets them apart, as the net structure introduces unique textures and visual interest. Moreover, eco advantages are significant when integrating biodegradable mesh or recyclable net materials. According to market research, the global packaging nets market is projected to grow from about USD 975 million in 2024 to over USD 1,404 million by 2035, with a CAGR around 3.4%. This rise stems from demand in fresh produce packaging and sustainable solutions.

Core Principles in Packaging Design Nets

Start With the Right Net (Fold Pattern)

Your net layout dictates how your package folds, how strong it will be, and how the mesh or perforated areas behave. There may be multiple net options for a single box form; choose one that minimises stress on the mesh areas and supports branding continuity.

Choose Materials Wisely

Mesh and net materials come in various forms, including plastic mesh (PE, PP), biodegradable or compostable polymers, cotton mesh, and jute fibres. Some designers prefer solid substrates with cutouts, using laser or die-cutting to achieve a net effect. Hybrid structures can also be created with solid edges or frames and net central sections. The material should suit your product’s weight, fragility, and perishability while aligning with your sustainability goals.

Ensure Structural Integrity

Since a net portion is often weaker than a solid wall, reinforcement is essential. You can add ribs or stiffer borders, incorporate internal supports, or limit open spans to smaller sections. Prototyping and testing under shipping conditions will help you ensure durability.

Focus on Branding and Graphic Flow

When graphics or logos pass through net or mesh areas, continuity matters. The design should flow smoothly, maintaining the viewer’s visual focus even through perforations. Choose ink types suited for mesh printing or substrates near the net cuts to avoid distortion.

Consider User Experience

Net packaging should be functional and user-friendly. It must open and close easily, have comfortable handles, and possibly be reusable. Safety is important too—edges of cutouts should not be sharp or prone to fraying.

Prioritise Sustainability

With sustainability at the forefront of design, brands must use recyclable or compostable net materials. Reduce total material usage, design for disassembly, and promote reuse, such as creating net bags that consumers can keep for shopping or storage.

Creative Applications and Industry Examples

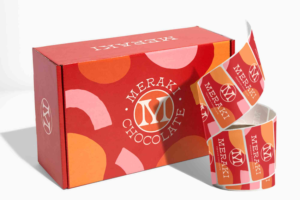

Packaging design nets find use in multiple sectors. In the fresh produce industry, net bags for citrus fruits, onions, and shellfish are common due to their airflow benefits and cost efficiency. The cosmetic and gift industries also use fine mesh sleeves over rigid boxes to add a luxurious feel while revealing the product inside. Decorative items like candles and ornaments often use nets to enhance visibility and texture. Retailers have even begun to combine rigid boxes with net windows, creating hybrid packages that tease product visibility while maintaining structure. In more experimental applications, designers use complex folded net structures for sculptural packaging, blending net and solid surfaces to craft bold, geometric designs.

Guide to Designing Packaging Design Nets

Product and Brand Audit

Understand the physical and emotional requirements of your product and brand. Determine your item’s size, fragility, and audience preferences before beginning the design.

Conceptual Sketching

Sketch different layouts and experiment with the balance of solid and mesh sections. Focus on how the net’s texture complements your brand story.

Material Selection

Choose materials based on strength, texture, and eco-friendliness. Request samples and test compatibility with your printing methods.

Prototype Development

Create physical mockups to test folding patterns, durability, and visual appeal. Test how your design handles shipping, stacking, and daily use.

Branding and Print Finishing

Integrate logos and graphics seamlessly across solid and net sections. Consider advanced finishing techniques such as embossing, varnishing, or foil stamping for premium effects. For professional advice on finishing techniques, visit print & finishing insights.

Production and Cost Planning

Estimate the cost per unit and explore how your design scales in manufacturing. Some net designs may require advanced cutting or assembly, which can affect pricing.

Testing and Feedback

Test with consumers and distributors before mass rollout. Collect feedback to refine usability, visual balance, and net durability.

Common Challenges and Solutions

One challenge is maintaining structural strength; the solution lies in adding reinforced borders and reducing large open net areas. Misaligned graphics can be prevented with proper bleed zones and spacing. While cost is sometimes higher, optimising production and sourcing at scale can reduce it. Recycling complications can be resolved by using materials of a single type and providing clear disposal instructions.

Trends and Future Directions

The future of packaging design nets is leaning towards sustainability and innovation. Biodegradable mesh and compostable polymers are becoming mainstream in response to stricter environmental regulations. Smart packaging is on the rise, with QR codes or RFID tags embedded in the mesh to provide digital connectivity. 3D printing allows personalised net patterns for different product lines, while minimalist cutout styles are redefining premium aesthetics. Circular design is also a growing trend, encouraging packages that transform into reusable items, such as mesh bags or decorative containers.

Packaging design nets offer a unique blend of beauty, efficiency, and environmental friendliness. They provide an elegant solution for brands seeking both transparency and protection. By combining thoughtful material selection, structural integrity, and sustainability principles, brands can achieve packaging that captivates consumers while remaining practical.

To bring your vision to life, explore Custom Packaging options tailored to your product’s needs. You can also visit Buddy Packaging Location for professional assistance. Let your packaging tell your story — start designing smarter, sustainable nets today.

Frequently Asked Questions

What is the difference between a packaging net and a traditional box?

A packaging net uses mesh or perforated surfaces, allowing visibility and airflow, unlike a traditional closed-wall box.

Are netted packaging designs suitable for all products?

Not entirely. They’re ideal for items requiring ventilation or visibility, such as produce, cosmetics, or handmade goods. Fragile items may need additional protection.

Do packaging design nets cost significantly more?

Costs can vary depending on materials and cutting techniques, but they’re often offset by material savings and brand value.

How do I make sure my net package is recyclable?

Use single-type materials, avoid coatings that hinder recycling, and clearly label disposal instructions.

Where can I see examples of net packaging?

You’ll find them in supermarkets for produce, in beauty stores for mesh-covered gift items, and on premium packaging trend showcases online.