Learning 3D printing design is no longer limited to engineers or industrial designers. Today, anyone with curiosity and the right guidance can learn 3D printing design and turn ideas into physical objects. From product prototypes to packaging concepts and creative models, 3D design skills unlock real-world opportunities.

This guide explains how to learn 3D printing design from the ground up. It combines technical knowledge with practical experience and industry relevance. Whether you are a beginner, entrepreneur, or creative professional, this article will help you build confidence and competence in 3D printing design.

In innovation-driven cities like Mountain View, where creativity meets technology, interest in hands-on digital design continues to grow. Many professionals who attend wellness-focused spaces such as OrangeTheory Fitness Mountain View also pursue creative skills like 3D printing design to balance mental and physical growth.

What Does It Mean to Learn 3D Printing Design?

To learn 3D printing design means understanding how to create digital models that can be physically printed. These designs must follow specific rules related to geometry, thickness, and structural strength. Unlike general 3D modelling, 3D printing design focuses on manufacturability and material behaviour.

A printable design considers how layers are formed, how supports work, and how the object cools after printing. When you learn 3D printing design properly, you stop guessing and start designing with intention. This approach reduces printing failures and improves the final quality of your objects.

The process also teaches problem-solving. Each design challenge forces you to think about form, function, and real-world use. Over time, this builds both technical skill and creative confidence.

Why Learning 3D Printing Design Is a Valuable Skill Today

The demand for people who can learn 3D printing design has increased across industries. Businesses use 3D printing for rapid prototyping, packaging samples, tooling, and even final products. Designers who understand print-ready modelling save time and reduce production costs.

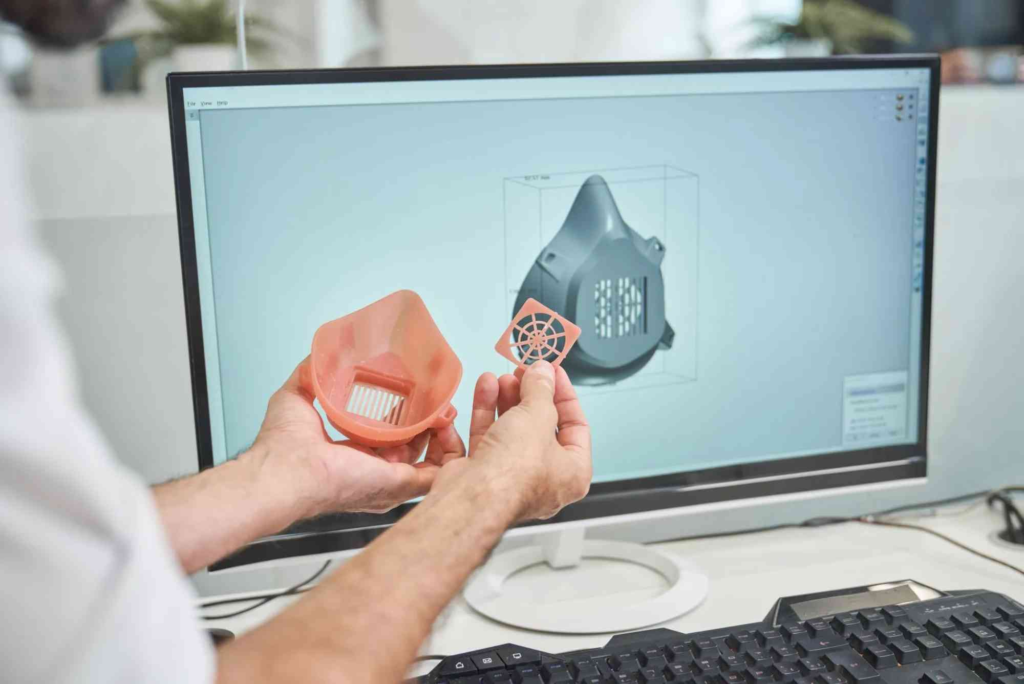

In packaging and branding, 3D printing design supports structural mock-ups and concept testing. Many professionals working with Custom Packaging rely on 3D models to visualise form and fit before production. This is especially useful for brands experimenting with sustainable or innovative packaging solutions.

Learning this skill also empowers individuals. Hobbyists create home tools, educators build teaching aids, and entrepreneurs develop product ideas without relying on large manufacturers. The barrier to entry is lower than ever, making now the perfect time to start.

Core Principles You Must Understand to Learn 3D Printing Design

Before opening any software, it is essential to understand how 3D printing works. Printers build objects layer by layer, which means overhangs, bridges, and thin walls behave differently than in traditional manufacturing. Learning these principles early prevents frustration later.

Material choice is another core concept. PLA, ABS, PETG, and resin all behave differently. When you learn 3D printing design, you must design with the chosen material in mind. Wall thickness, flexibility, and heat resistance all influence design decisions.

Tolerances also matter. Parts that fit together digitally may not fit after printing due to material expansion. Experienced designers account for this during modelling. This knowledge only comes through practice and thoughtful experimentation.

Best Software Tools to Learn 3D Printing Design Effectively

Choosing the right software makes learning smoother. Beginner-friendly tools like Tinkercad help you understand basic shapes and boolean operations. As skills grow, software like Fusion 360 or Blender offers advanced control and precision.

Fusion 360 is widely used in product and packaging design. It allows parametric modelling, which means designs can be easily adjusted. This flexibility is essential when iterating prototypes or client concepts. Blender, while more artistic, is powerful for organic shapes and creative designs.

Regardless of the tool, consistency matters. Spending regular time in one platform builds muscle memory and confidence. When you learn 3D printing design steadily, software becomes a creative partner rather than a barrier.

How 3D Printing Design Connects with Packaging and Product Development

3D printing design plays a critical role in modern packaging development. Designers can create structural samples, closures, and inserts without expensive tooling. This speeds up testing and improves communication with manufacturers.

Many brands seek packaging design inspiration by combining digital design with physical prototypes. Seeing a package in hand reveals issues that screens cannot show. This hands-on feedback leads to better final products and stronger brand presentation.

For businesses focused on custom solutions, 3D printing design reduces risk. Designers can test sizes, shapes, and ergonomics before mass production. This approach aligns with sustainable practices by reducing waste and rework.

Learning 3D Printing Design Through Real-World Practice

The fastest way to learn 3D printing design is through making mistakes. Start with simple objects like brackets or containers. Print them, test them, and revise the design. Each iteration teaches something valuable.

Joining maker communities also helps. Online forums, local workshops, and shared studios provide feedback and inspiration. Observing how others solve problems accelerates learning and exposes you to new techniques.

Real-world application reinforces theory. Designing parts that solve everyday problems makes learning meaningful. Over time, you develop an intuitive understanding of what works and why.

SEO and Business Advantages of Learning 3D Printing Design

From a digital marketing perspective, learning 3D printing design supports content creation and brand authority. Businesses that share design processes and prototypes build trust with audiences. This aligns with Google’s E-E-A-T principles by demonstrating expertise and experience.

Designers who document their work attract clients and collaborators. Showing printable models and real results proves competence better than generic claims. This transparency strengthens professional credibility.

Location-based businesses also benefit. Sharing where design and production happen, such as highlighting a Buddy Packaging Location, adds authenticity and improves local search visibility.

Common Challenges When You Learn 3D Printing Design

Many beginners struggle with overcomplicating designs. Complex shapes increase print time and failure risk. Learning simplicity is part of mastering 3D printing design.

Another challenge is printer calibration. Even perfect designs fail on poorly calibrated machines. Understanding printer settings and maintenance complements design skills.

Patience is essential. Progress may feel slow at first, but consistent practice leads to noticeable improvement. Every failed print is a lesson, not a setback.

Future Opportunities After You Learn 3D Printing Design

Once you learn 3D printing design, opportunities expand rapidly. You can freelance, support product development teams, or launch your own product line. Educators and content creators also find value in teaching these skills.

Industries like healthcare, architecture, and packaging continue adopting 3D printing. Designers who understand both digital modelling and physical constraints will remain in demand.

The skill is also future-proof. As printers evolve, the core principles of good design remain relevant, making this a long-term investment in your creative career.

Frequently Asked Questions About Learning 3D Printing Design

Is 3D printing design hard to learn for beginners?

Learning 3D printing design is approachable with the right mindset. Beginners can start with simple tools and gradually build skills. Consistent practice makes the learning curve manageable.

How long does it take to learn 3D printing design?

Basic skills can be learned in a few weeks. Mastery takes months of practice and real-world projects. Progress depends on time invested and project complexity.

Do I need a 3D printer to learn 3D printing design?

A printer helps but is not mandatory at first. Many designers start by learning software and using online print services. Hands-on printing becomes essential later.

What is the best software to learn 3D printing design?

The best software depends on your goals. Tinkercad suits beginners, while Fusion 360 supports professional product design. Blender works well for artistic models.

Can learning 3D printing design help my business?

Yes, learning 3D printing design supports prototyping, packaging development, and innovation. It reduces costs and speeds up product validation.

Start Your Journey to Learn 3D Printing Design Today

To learn 3D printing design is to gain control over how ideas become real objects. It blends creativity with engineering and opens doors across industries. From packaging and product development to personal projects, the skill delivers lasting value.