Car Subwoofer Box Design Plans

If you are a car audio enthusiast, you understand the impact of a well-designed subwoofer box. A subwoofer’s performance heavily depends on its enclosure, and having solid car subwoofer box design plans ensures optimal sound quality, deep bass, and minimal distortion. This guide covers everything from choosing the right design to building your subwoofer box, with practical tips for both beginners and experienced DIYers.

Understanding Subwoofer Enclosures

Before diving into design plans, it’s crucial to understand the types of subwoofer enclosures and how they affect sound performance.

Sealed Enclosures

Sealed boxes are airtight and provide tight, accurate bass. They are ideal for small spaces and are simpler to build. The downside is they require more power to reach high volume levels.

Ported Enclosures

Ported or vented boxes include a port or tube that enhances low-frequency output. They produce louder bass with less power but are more complex to design and build.

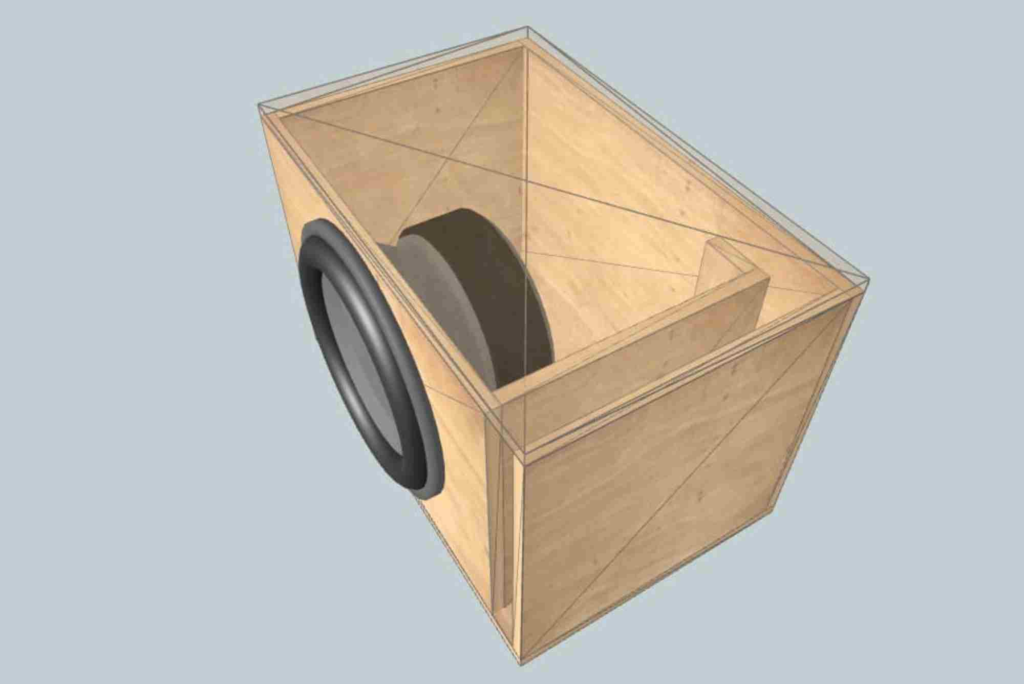

Bandpass Enclosures

Bandpass boxes are a hybrid of sealed and ported designs. They are highly efficient at certain frequencies, delivering booming bass, but they require precise tuning for the subwoofer.

Key Factors in Car Subwoofer Box Design Plans

Designing a subwoofer box involves more than cutting wood and screwing it together. Several factors influence sound quality.

Subwoofer Size and Type

Different subwoofers require different box sizes. Check the manufacturer’s recommended enclosure volume to ensure the best performance.

Material Selection

Use dense materials like MDF or plywood for a solid, vibration-free enclosure. Avoid particle board, as it may warp or rattle.

Internal Volume and Dimensions

The internal volume of the box affects bass response. Follow the recommended dimensions from your subwoofer’s datasheet. Small miscalculations can impact sound quality.

Port Tuning

If building a ported box, the port’s length and diameter determine the tuning frequency. Use online calculators to fine-tune your port.

Bracing and Sealing

Bracing reinforces the box, preventing flexing, while proper sealing avoids air leaks that reduce efficiency. Use silicone or wood glue for airtight construction.

Step-by-Step Car Subwoofer Box Design Plans

Creating your own subwoofer box can be a fun DIY project if approached systematically.

Gather Materials

You will need MDF or plywood, wood screws, clamps, silicone sealant, a jigsaw, drill, measuring tape, and sandpaper. Proper tools ensure accurate cuts and smooth finishes.

Choose a Design

Select a design type based on your listening preference: sealed, ported, or bandpass. Consider your car’s space limitations before finalizing.

Calculate Dimensions

Use online calculators or the subwoofer’s specifications to determine box volume and dimensions. Accurate measurements are crucial for optimal bass performance.

Cut and Assemble Panels

Carefully cut all panels to size. Assemble the box using screws and wood glue. Ensure corners are square to avoid air leaks.

Add Bracing

Install internal braces to reduce vibrations. Custom Boxes Braces also improve overall sound quality by keeping panels rigid during high-volume playback.

Seal the Box

Apply silicone sealant to all internal seams. A well-sealed box prevents air leaks, which can cause distortion and reduce bass output.

Install Subwoofer

Mount the subwoofer securely, ensuring the speaker fits snugly. Avoid over-tightening screws, which may damage the subwoofer frame.

Test and Fine-Tune

Play test tracks to evaluate bass response. Adjust the port or subwoofer position if necessary. Tuning your box may take several iterations to achieve perfect sound.

Tips for Better Car Subwoofer Performance

- Choose Custom Boxes for pre-made, precise designs.

- Keep wiring short and clean to reduce power loss.

- Avoid placing the subwoofer too close to the car walls to prevent rattling.

- Use damping material inside the box to absorb internal vibrations.

- Refer to print & finishing insights for high-quality finishes that prevent wear and tear.

Common Mistakes to Avoid

- Overlooking subwoofer specifications

- Using low-quality materials

- Poor sealing or incorrect port tuning

- Oversized or undersized boxes

- Ignoring bracing and internal support

Well-executed car subwoofer box design plans are essential for superior sound quality. Whether building a sealed, ported, or bandpass box, attention to detail makes a significant difference. Take your time, follow recommended specifications, and don’t hesitate to test and adjust. For DIYers seeking guidance, resources like Buddy Packaging Location can provide additional insights on materials and finishes.

Enhance your car audio experience today by designing or upgrading your subwoofer box with expert plans and tips.

FAQ

What is the best type of subwoofer box for deep bass?

Sealed boxes offer tight, accurate bass, while ported boxes provide louder low frequencies. The choice depends on your space and power.

How do I calculate the correct box size?

Refer to your subwoofer’s specifications for recommended volume. Online calculators can help convert volume to dimensions.

Can I build a subwoofer box with plywood?

Yes, plywood is durable and works well. MDF is preferred for its density and vibration resistance.

How do I tune a ported subwoofer box?

Adjust the port length and diameter using calculators or manufacturer recommendations to achieve the desired frequency response.

Do I need internal bracing?

Yes, bracing reduces panel vibrations, improving bass clarity and preventing box flexing.

How can I prevent rattling in my car subwoofer box?

Ensure airtight sealing, add bracing, and use damping materials inside the box to minimize vibrations.