The packaging design process is more than making a box look attractive. It is a strategic journey that blends creativity, engineering, branding, and consumer psychology. When done well, packaging protects the product, communicates value, and influences buying decisions at the shelf and online.

In competitive markets, brands that invest time in a structured packaging design process gain trust and recognition faster. This article explains each stage in depth, using real-world insight and practical experience. You will learn how successful packaging moves from an idea to a finished product that performs commercially and emotionally.

Understanding the Purpose of the Packaging Design Process

Before design work begins, it is essential to understand why packaging exists. Packaging must protect the product, comply with regulations, and reflect the brand identity clearly. At the same time, it needs to attract attention in seconds.

The packaging design process aligns business goals with user expectations. It ensures that design decisions are not based on trends alone. Instead, they are guided by research, usability, and long-term brand consistency. This approach reduces costly redesigns and production errors later.

Research and Discovery in the Packaging Design Process

Every effective packaging design process starts with research. This stage shapes all creative and technical decisions that follow.

Market and Competitor Analysis

Understanding the market context is crucial. Designers analyse competing products to see what works and what feels overused. This helps brands stand out without confusing customers.

At this stage, attention is given to colours, materials, typography, and structure used by competitors. The aim is differentiation, not imitation. Strong packaging often borrows category cues while adding a unique twist.

Understanding the Target Audience

Packaging should speak directly to its intended user. Age, lifestyle, values, and buying habits all influence design choices. For example, premium buyers expect refined finishes, while eco-conscious shoppers value sustainable materials.

The packaging design process considers how and where customers interact with the product. Is it bought online or in-store? Is it a gift or a daily essential? These answers shape the design direction early.

Brand Strategy and Concept Development

Once research is complete, the focus shifts to brand alignment. This stage connects business identity with visual expression.

Translating Brand Values into Design

Packaging is often the first physical touchpoint with a brand. It must reflect tone, personality, and promise. A playful brand may use bold colours and informal language. A luxury brand may rely on minimal design and tactile finishes.

During the packaging design process, designers create mood boards and concepts. These help visualise how the brand story will appear on packaging. Decisions made here influence trust and recognition.

Structural Design and Functionality

Structure is as important as visuals. The shape and opening experience affect usability and perception. Poor structure can damage products or frustrate customers.

Designers consider weight, size, storage, and transportation. Efficient structures reduce costs and environmental impact. Many brands exploring Custom Packaging solutions focus heavily on this stage to balance creativity with practicality. You can explore tailored structural approaches through this guide on Custom Packaging.

Visual Design and Artwork Creation

This is where the packaging design process becomes visible. Visual design transforms strategy into something customers can see and touch.

Typography, Colours, and Imagery

Typography must be legible and appropriate for the brand voice. Colours choices influence emotion and recall. Imagery should support the message, not overwhelm it.

Designers test layouts to ensure key information is clear. Product names, benefits, and legal details must be easy to find. This clarity improves both shelf impact and customer confidence.

Regulatory and Information Design

Packaging must comply with local regulations. This includes ingredient lists, safety warnings, and recycling symbols. Ignoring these requirements can delay launches or cause legal issues.

Experienced designers integrate compliance seamlessly. The packaging design process ensures that mandatory information does not compromise aesthetics or readability.

Material Selection and Sustainability Considerations

Material choice affects cost, durability, and brand perception. It also plays a growing role in sustainability.

Choosing the Right Materials

Designers evaluate materials based on product needs and distribution conditions. Fragile items require protective materials. Food products need barrier properties for freshness.

Material decisions are tested for performance and appearance. Finishes such as matte, gloss, or textured coatings add sensory value. Reliable industry insights can be found through professional resources like print & finishing insights, which explore evolving print technologies.

Sustainable Packaging Design

Sustainability is no longer optional. Many consumers expect recyclable or biodegradable packaging. The packaging design process now includes life-cycle thinking.

Designers aim to reduce material use without compromising protection. Clear recycling instructions also help customers dispose of packaging responsibly. Sustainable choices strengthen brand credibility.

Prototyping and Testing in the Packaging Design Process

Before mass production, designs must be tested in real conditions.

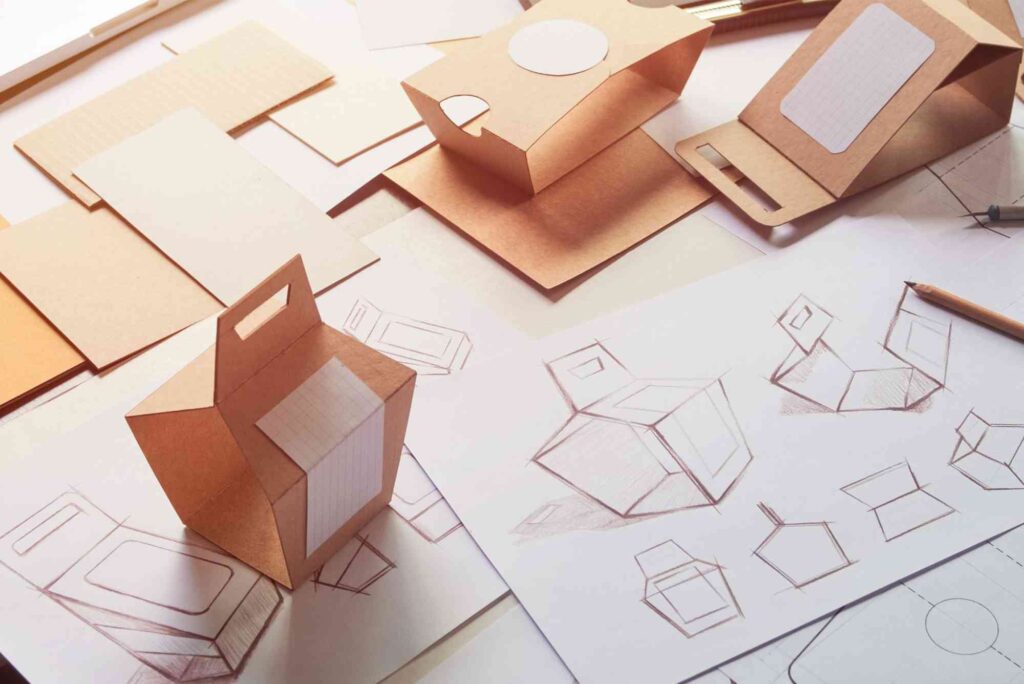

Physical Prototypes and Mock-ups

Prototypes allow designers and stakeholders to assess size, feel, and usability. They reveal issues that digital designs cannot show. Opening experience, durability, and stacking efficiency are tested.

This stage saves time and money. Fixing problems during prototyping is far cheaper than correcting them after production.

Consumer and Quality Testing

Some brands test packaging with real users. Feedback highlights confusion, appeal, or usability issues. Quality tests simulate transport and storage conditions.

The packaging design process becomes stronger when real-world feedback is used to refine details. This step increases confidence before final approval.

Production and Print Management

Production is where design meets reality. Clear communication with suppliers is essential.

Print Preparation and Colours Management

Design files are prepared according to printer specifications. Colours accuracy is carefully managed to ensure consistency across batches.

Designers often attend press checks to approve samples. This hands-on involvement reflects professional experience and protects design integrity.

Quality Control and Timelines

Quality checks ensure materials, colours, and finishes meet expectations. Timelines are monitored closely to meet launch dates.

Strong supplier relationships improve reliability. Brands that manage this stage well reduce delays and unexpected costs.

Distribution, Retail, and Shelf Performance

Packaging must perform beyond the factory. It needs to survive distribution and succeed at the point of sale.

Logistics and Storage Considerations

Efficient packaging reduces shipping costs and damage. Stackability and weight are considered during the packaging design process.

Designs that optimise space benefit both retailers and e-commerce operations. This practical thinking improves profitability.

Retail and Unboxing Experience

In-store, packaging must stand out quickly. Online, the unboxing experience matters more than ever. Thoughtful details create memorable moments that encourage repeat purchases.

Packaging that photographs well also supports digital marketing and social sharing.

Measuring Success and Iteration

The packaging design process does not end at launch. Performance should be reviewed regularly.

Sales data, customer feedback, and damage reports offer valuable insight. Brands that iterate based on evidence stay competitive. Small refinements can lead to significant improvements over time.

Frequently Asked Questions About the Packaging Design Process

What are the main steps in the packaging design process?

The packaging design process includes research, concept development, structural and visual design, prototyping, testing, production, and review. Each stage builds on the previous one to reduce risk and improve results.

How long does the packaging design process take?

Timelines vary by complexity. Simple packaging may take weeks, while complex projects can take several months. Research and testing often require the most time.

Why is packaging design important for branding?

Packaging is a physical representation of a brand. It influences first impressions, trust, and perceived value. Strong design supports recognition and loyalty.

How does sustainability affect packaging design?

Sustainability influences material choice, structure, and messaging. Brands increasingly design packaging to reduce waste and improve recyclability.

Can small businesses benefit from a structured packaging design process?

Yes, a clear packaging design process helps small businesses avoid costly mistakes. It ensures packaging aligns with brand goals and customer expectations from the start.

Why the Packaging Design Process Matters

The packaging design process is a strategic investment, not a decorative exercise. It combines research, creativity, and technical expertise to deliver packaging that works in the real world.

Brands that respect this process create packaging that protects products, communicates value, and builds trust. From first sketch to final print, every decision matters.

If you are looking to improve your packaging or start a new project, working with experienced professionals makes a measurable difference. To explore expert support and see where tailored packaging solutions begin, visit the Buddy Packaging Location and connect with specialists who understand every stage of the journey: Buddy Packaging Location.