Introduction

The world of design and manufacturing is undergoing a remarkable transformation, and at the centre of it lies 3D printing design objects. What was once a futuristic concept has now become a mainstream technology, empowering designers, engineers, and artists to turn their digital visions into tangible realities. From intricate art pieces to functional mechanical parts, 3D printing enables creativity without boundaries.

In this comprehensive guide, we’ll explore what 3D printing design objects are, how they’re created, the tools and techniques involved, and how they’re shaping industries worldwide.

Understanding 3D Printing Design Objects

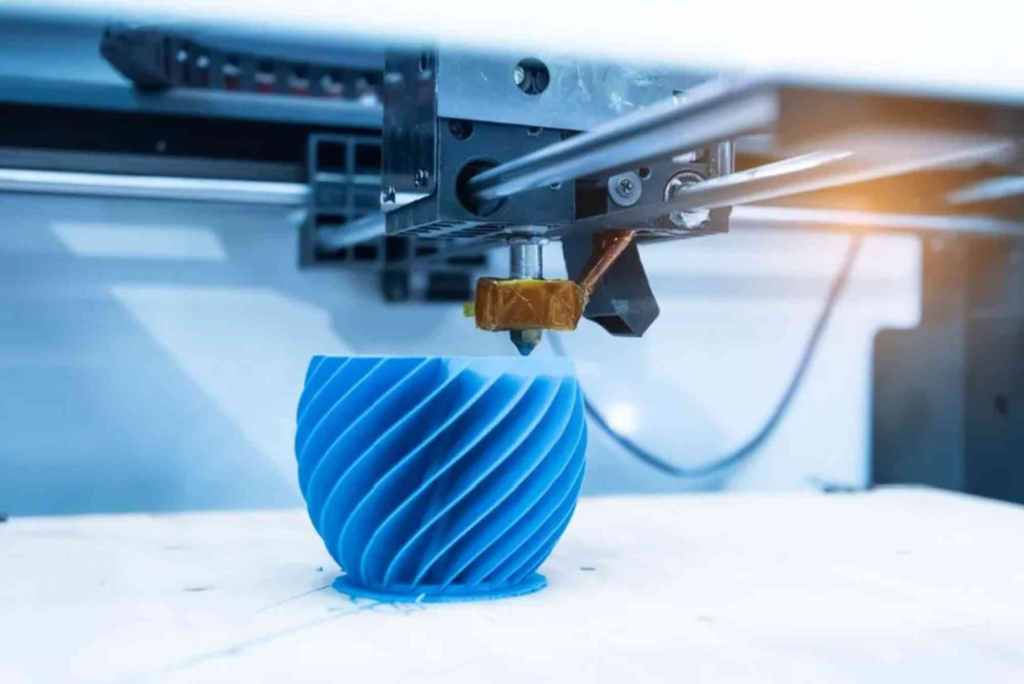

3D printing, or additive manufacturing, is the process of building objects layer by layer from digital models. Unlike traditional subtractive manufacturing methods that carve or cut materials away, 3D printing constructs designs from the ground up.

When we talk about 3D printing design objects, we refer to the digital models and physical creations produced through this technology. These can include prototypes, sculptures, jewellery, furniture, or even architectural models.

The beauty of 3D printing lies in its versatility — whether you’re a product designer, hobbyist, or entrepreneur, it allows you to experiment, test, and refine ideas rapidly.

The Process of Creating 3D Printing Design Objects

Concept and Ideation

Every great design begins with an idea. The process starts by identifying the object’s purpose — whether it’s aesthetic, functional, or experimental. Designers brainstorm concepts, often drawing packaging design inspiration from existing creations or nature itself. For example, an industrial designer might study organic shapes to produce more ergonomic products.

3D Modelling

Next comes the design phase, where the concept is turned into a 3D model using specialised software such as Blender, Fusion 360, or SolidWorks. These programs allow designers to sculpt, measure, and simulate the object’s form and function before printing.

Precision is crucial at this stage. Even a minor error in scale or proportion can affect the final print. Many designers use open-source models as a base and then customise them to suit their unique vision.

Slicing and Preparation

Once the 3D model is ready, it must be “sliced.” This means the design is converted into thin layers that the printer can read. The slicing software also determines printing parameters like layer height, infill density, and speed.

This stage bridges the digital and physical worlds — ensuring that the virtual model becomes a viable print.

Printing the Object

With the model prepared, the 3D printer takes over. Depending on the material — which could range from plastic and resin to metal or bio-materials — the printer builds the object layer by layer.

Different 3D printing technologies exist, such as:

- Fused Deposition Modelling (FDM): Ideal for prototypes and low-cost models.

- Stereolithography (SLA): Offers high detail, often used for jewellery and art.

- Selective Laser Sintering (SLS): Suitable for industrial-grade components.

Each technique has its advantages, and choosing the right one depends on the desired quality, material strength, and cost.

Post-Processing

After printing, the object usually requires finishing touches. This can include sanding, polishing, painting, or even assembling multiple parts. The post-processing phase enhances both the aesthetics and functionality of the 3D printed design.

For professionals working in industries like product design or custom packaging, this phase is particularly important — the final presentation often determines client satisfaction and usability.

Applications of 3D Printing Design Objects

The influence of 3D printing design objects extends across countless industries. Here are some of the most notable applications:

Art and Design

Artists and sculptors are using 3D printing to push creative boundaries. Complex structures that once took months to carve can now be produced within hours. The ability to experiment with materials and shapes has sparked a new era of digital artistry.

Product Prototyping

Before mass production, designers rely on 3D printing to test product ideas. This process allows for rapid prototyping, saving both time and cost. Engineers can identify flaws early, refine designs, and present accurate models to stakeholders.

Fashion and Jewellery

3D printing in fashion has opened a new world of personalised style. Jewellery designers can craft intricate patterns impossible by hand, while fashion designers use printed materials to create avant-garde pieces that merge art and technology.

Architecture and Construction

Architectural models are essential in communicating spatial ideas. 3D printing makes it possible to produce detailed, scalable models that accurately represent real-world designs. In some cases, entire building components are 3D printed using concrete mixtures.

Healthcare and Medicine

From custom prosthetics to dental implants, the healthcare industry has embraced 3D printing for its ability to create tailored solutions. The precision and adaptability of this technology are transforming medical innovation.

Education and Research

Universities and research labs use 3D printing as a teaching and experimentation tool. It encourages students to understand complex engineering concepts and design principles in an interactive, hands-on way.

Advantages of 3D Printing Design Objects

The growing popularity of 3D printing stems from several compelling advantages.

Creativity Without Limits

Traditional manufacturing often limits design possibilities due to tooling restrictions. With 3D printing, designers can create intricate geometries and structures that were once impossible.

Cost-Effectiveness

By eliminating the need for expensive moulds and tooling, 3D printing makes small-scale production more affordable. It’s particularly useful for startups looking to bring products to market quickly.

Speed and Flexibility

3D printing dramatically reduces production time. Designers can print prototypes overnight, test them, and make modifications instantly. This speed enables innovation at an unprecedented pace.

Sustainability

Many 3D printing materials are recyclable, and the process itself minimises waste compared to traditional manufacturing. As sustainability becomes a global priority, 3D printing offers a greener alternative.

Challenges in 3D Printing Design

Despite its benefits, 3D printing comes with challenges. Material limitations can restrict durability or finish quality. High-end printers and materials can be expensive, and achieving precision requires skill and experience.

Additionally, file errors or calibration issues can lead to failed prints — something every 3D designer learns to manage through trial and error. However, as technology advances, these obstacles are steadily diminishing.

The Role of 3D Printing in Custom Packaging

One of the most exciting developments in recent years is the integration of 3D printing in Custom Packaging. Businesses are using 3D printing to prototype packaging designs, test structural integrity, and create limited-edition or luxury packaging solutions.

It allows companies to design and test concepts quickly before full-scale production, improving both design and customer experience. Brands that experiment with 3D printed packaging gain a significant edge in creativity and sustainability.

For more creative design ideas and packaging design inspiration, explore Packaging of the World — a hub showcasing innovative design projects from around the globe.

Future Trends in 3D Printing Design

As 3D printing continues to evolve, several emerging trends are set to redefine design and production:

- Multi-Material Printing: The ability to print using different materials simultaneously will unlock hybrid designs combining strength and flexibility.

- AI-Assisted Design: Artificial intelligence will soon generate optimised structures for improved performance and efficiency.

- Bioprinting: The printing of organic materials for medical purposes is one of the most promising frontiers.

- Mass Customisation: From footwear to home décor, personalised 3D printed products will become the norm rather than the exception.

FAQs

What software is best for designing 3D printing objects?

Popular choices include Blender, Fusion 360, Tinkercad, and SolidWorks. The choice depends on your experience level and design complexity.

Can 3D printing be used for mass production?

Yes, but it’s typically more efficient for small batches or customised products. However, advancements in industrial printers are changing this rapidly.

What materials can be used in 3D printing?

Common materials include PLA, ABS, resin, nylon, and metal powders. Each offers different properties for strength, flexibility, or finish.

How accurate is 3D printing?

High-end printers can achieve micron-level precision. Accuracy largely depends on the printer type, material, and calibration.

Is 3D printing environmentally friendly?

Compared to traditional methods, yes. It reduces material waste and energy use, especially when using biodegradable or recycled materials.

3D printing design objects represent more than a technological advancement — they symbolise a creative revolution. This innovation bridges the gap between imagination and reality, empowering designers to create faster, smarter, and more sustainably.