Introduction

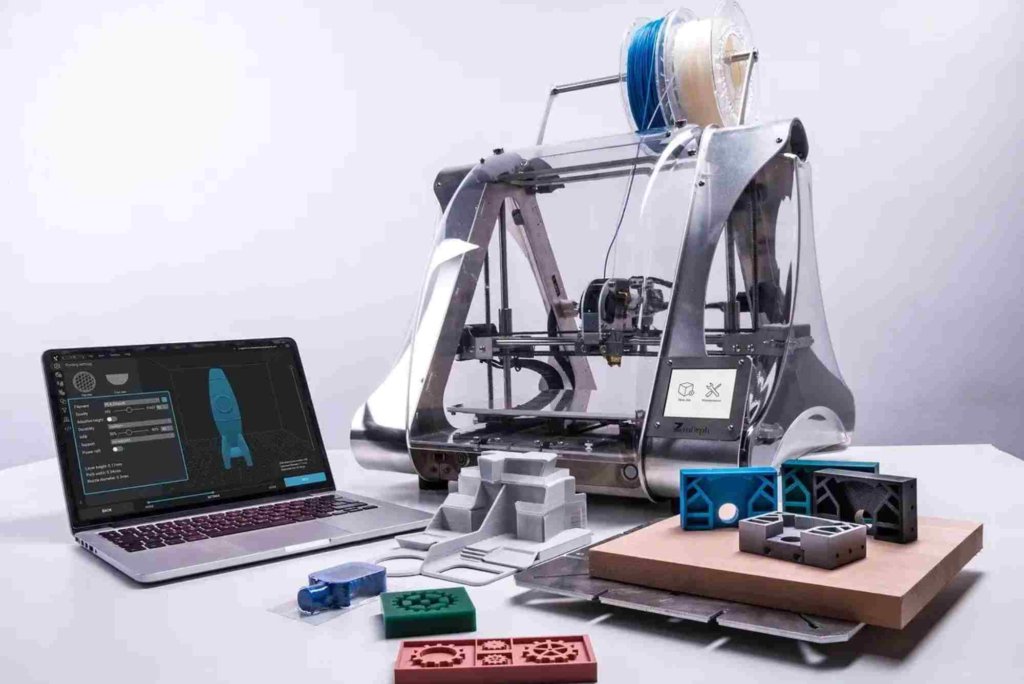

3D printing has revolutionised manufacturing, prototyping, and custom design. However, achieving high-quality results requires more than just sending a file to a printer. Understanding and following proper 3D printing design guidelines can save time, reduce material waste, and enhance the final product’s durability and functionality.

Understanding the Basics of 3D Printing

Before diving into design specifics, it is essential to grasp how 3D printing works. Essentially, a 3D printer builds objects layer by layer from digital models. The technology supports multiple materials, including plastics, resins, and metals, each with distinct characteristics. Knowing the strengths and limitations of the chosen material helps in designing parts that are both functional and efficient.

Importance of Layer Height and Resolution

Layer height directly impacts the surface finish and structural integrity of a printed part. Lower layer heights produce finer detail but increase printing time. Designers must balance visual quality with efficiency, especially when producing prototypes or functional parts. Considering the printer’s resolution ensures features are accurately represented without unnecessary complications.

Material Selection

Material choice is crucial for strength, flexibility, and aesthetics. For instance, PLA is easy to print and ideal for prototypes, while ABS offers durability and heat resistance. Engineering applications may require specialized materials such as nylon or carbon fibre composites. Correctly matching material properties with design intent ensures functional and reliable outcomes.

Geometry and Structural Considerations

Good geometry design is a cornerstone of effective 3D printing. Certain shapes and angles can affect the printability, strength, and post-processing requirements.

Wall Thickness

Maintaining consistent wall thickness improves strength and reduces warping. Extremely thin walls may lead to fragile parts, while overly thick walls can increase material usage unnecessarily. Designers should consider both the minimum and maximum wall thickness recommended for the chosen material and printer.

Overhangs and Supports

Overhangs exceeding the printer’s capabilities often require support structures. Excessive supports can increase post-processing effort and waste material. Designing parts with self-supporting angles, typically under 45 degrees, minimises the need for additional support while maintaining structural integrity.

Holes and Internal Features

Holes and cavities must be designed with the printer’s tolerances in mind. Small holes may close up during printing, and intricate internal features can trap excess material or lead to weak points. Using chamfers, fillets, or slightly enlarging holes ensures functional accuracy.

Optimising Design for Strength and Durability

Strength and durability are critical in functional applications. Understanding load paths and stress distribution allows designers to optimise the geometry for performance.

Fillets and Chamfers

Sharp corners create stress concentrations, increasing the risk of cracks. Incorporating fillets or chamfers distributes stress more evenly, enhancing durability. Rounded edges also improve layer adhesion, reducing potential print failures.

Reinforcement Strategies

Internal ribbing, honeycomb structures, and lattice infills add strength without significantly increasing weight. Selecting the appropriate infill pattern and density influences mechanical properties while conserving material.

Orientation and Print Direction

Print orientation affects strength, surface finish, and support requirements. Aligning critical load-bearing features with the printing layers ensures optimal strength. Designers should simulate stress directions and adjust the model orientation to reduce failure risks.

Design for Efficiency and Material Conservation

Efficient design saves time, reduces waste, and lowers production costs. Following material-conscious guidelines enhances the sustainability of 3D printing projects.

Minimising Material Usage

Hollowing out large solid sections, using infill patterns, and optimising wall thickness reduce material consumption. Strategic design choices can maintain structural integrity while conserving resources.

Reducing Print Time

Simplifying complex geometries, minimising overhangs, and optimising support structures reduce printing time. Faster prints not only save energy but also accelerate prototyping cycles and production schedules.

Modular Design

Designing modular parts that can be printed separately and assembled later allows for larger or more complex structures without exceeding printer limitations. Modular approaches also improve repairability and reduce waste if only certain components fail.

Post-Processing and Tolerances

3D printing rarely produces a perfect finished product directly from the printer. Considering post-processing during the design phase ensures a smoother workflow.

Allowances for Assembly

When designing parts to fit together, account for tolerances and material shrinkage. Slightly larger holes or slightly smaller pegs accommodate post-processing adjustments and ensure proper fit.

Surface Finishing

Surface texture can impact aesthetics, function, and assembly. Features that require smooth surfaces, such as sliding interfaces, should be designed with post-processing in mind, whether sanding, polishing, or chemical smoothing is used.

Cleaning and Support Removal

Designing parts for easy support removal and cleaning reduces production time and avoids damage. Accessible angles and detachable sections simplify post-processing, particularly for intricate designs.

Practical Tips for Design Success

In addition to technical considerations, designers benefit from general practical tips to streamline their 3D printing workflow.

Iterative Prototyping

Testing smaller versions or sections of a design allows identification of weaknesses before committing to a full print. Iterative prototyping reduces material waste and ensures functional reliability.

Collaboration with Manufacturing

Communicating design intent with the printing service or in-house technician ensures compatibility with the printer’s capabilities. Experienced operators may suggest adjustments that improve strength, accuracy, and finish.

Learning from Existing Guidelines

Established 3D printing communities, online resources, and guides provide valuable insights. For example, reviewing packaging design tips can inspire creative solutions for functional and aesthetically pleasing designs in industrial and consumer applications.

Integrating Design into Broader Applications

3D printing is increasingly used beyond prototyping, including in consumer products, custom solutions, and industrial parts. Considering broader applications enhances the value of the design.

Custom Applications

From personalised accessories to specialised industrial tools, 3D printing enables customised solutions. Working with services offering Custom Packaging or bespoke components ensures designs are not only functional but also market-ready.

Location-Specific Considerations

Manufacturing constraints may vary depending on location. Understanding the capabilities of a nearby facility, such as Buddy Packaging Location, allows designers to optimise designs for available technologies and materials.

Sustainability

Sustainable practices are essential in modern design. Reducing material use, designing for recyclability, and choosing eco-friendly materials align with environmental responsibility while maintaining quality.

Following comprehensive 3D printing design guidelines ensures that projects are not only technically feasible but also functional, durable, and efficient. By considering geometry, material properties, print orientation, and post-processing needs, designers can minimise errors, reduce waste, and maximise the potential of 3D printing technology. Whether producing prototypes, consumer products, or industrial components, these guidelines form the foundation of successful 3D printed designs.

Start applying these principles today and elevate your 3D printing projects. Explore more resources and professional solutions to enhance your designs and bring ideas to life.

FAQ

What is the most important factor in 3D printing design?

Material selection and wall thickness are critical. They influence strength, accuracy, and the printer’s ability to successfully create the object.

How do I prevent warping in 3D prints?

Use consistent wall thickness, appropriate support structures, and correct print orientation. Temperature control and proper bed adhesion also help.

Can 3D printed parts be strong enough for functional use?

Yes, with correct material choice, infill patterns, and reinforcement strategies, 3D printed parts can handle functional loads effectively.

Why is print orientation important?

Layer orientation affects mechanical strength and surface quality. Aligning features with load paths reduces the risk of failure.

How can I save material in 3D printing?

Hollowing parts, using infill patterns, and designing modular components reduce material consumption without sacrificing strength.